Welcome to CRS

We Are Here to Increase Your Knowledge With Experience

For over 40 years, CRS has been a worldwide leader in industrial fluid and solid material management. With operations in North America, Europe, and Asia, our recycling facilities convert used fluids into specified performance levels, allowing high-yield waste recovery and lower unit costs. As evidence of our partnership longevity, we have served a global Fortune 500 aluminum manufacturer since 1984, recycling over 1.16 billion gallons of production oil without interruption.

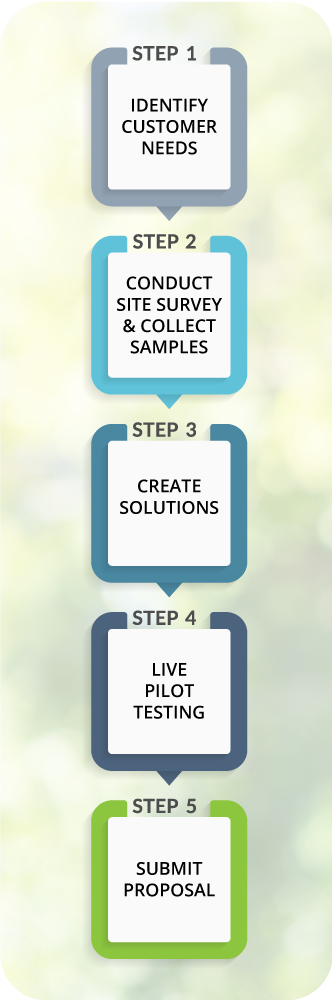

At CRS, we design the most cost-effective solution for your processes based on your specifications with an eye on sustainability and efficiency.